Jet Mills Jet Mill Equipment for Milling Size ...

Milling Equipment. A Complete Line of Efficient, Accurate, HighProductivity MicronMaster® Jet Pulverizers and the new USDA Accepted PharmaMaster®. For Chemical, Pharmaceutical, Food, .

WhatsApp)

WhatsApp)

Milling Equipment. A Complete Line of Efficient, Accurate, HighProductivity MicronMaster® Jet Pulverizers and the new USDA Accepted PharmaMaster®. For Chemical, Pharmaceutical, Food, .

The first step of processing corn germ from wet milling or dry milling is to ... The solvent extraction process uses hexane or other solvents to wash the corn oil from the prepared flakes or press cake. The design of the equipment varies so that Crown can optimize the amount of solvent and bed depth needed to efficiently wash the flakes, the ...

Corn wet milling – Starch industry equipment Through its'' and Sprout brands, ANDRITZ has been supplying equipment to the corn starch industry for over 100 years. The degerming machines supplied today represent the most modern of design while maintaining the exact same performance characteristics for which we are known.

The main component of wet overflow ball mill is a cylinder with bigger diameter and smaller length which is revolved by transmitting machinery. Materials are put in cylinder through the feed opening and then thoroughly grinded. The falling course of iron balls and ores can produce huge falling impact and autogenous is a high technological enterprise that integrated .

kuwait wet milling process equipment price. kuwait wet milling process equipment for sale aggregate crusher prices in kuwait ore . Get Price And Support Online; ICM INC Ethanol Production Process. GasFired Equipment . Ethanol Production Process. Ethanol is commercially produced using either a wet mill or dry mill process.

Dewatering equipment is designed as such to help separate water from solids using force, including vacuum and centrifugal motion. Dewatering equipments are used widely in waste management. Dewatering equipment .

Corn wet milling – Starch industry equipment Through its'' and Sprout brands, ANDRITZ has been supplying equipment to the corn starch industry for over 100 years. The degerming machines .

Wet Milling Process Equipment Price. Corn wetmilling market by end product starches, sweeteners, ethanol, and gluten feed gluten meal, application feed, food, and industrial, source dent and waxy, and equipment milling, steeping, and centrifuge system global forecast to hfcs is the key product manufactured in the wetmilling process, increase in its.

Get the best deals on Metalworking Machining Centers Milling Machines when you shop the largest online selection at Free shipping on many items ... Right Angle Milling Metalworking Equipment. Bridgeport Boring Head In Metalworking Milling Tooling. dynapath cnc. Mini Cnc Mill In Milling Machines.

During this process, foreign materials and all but the maize kernel is removed from the grain that is to be milled. These foreign materials, as well as the husk, dust, sand and straw, lowers the quality of the kernel. This process also involves the removal of any poisonous seeds and materials which might be harmful to the milling equipment.

Aug 06, 2018· The process involves grinding up an asphalt surface (anywhere from a couple of inches to a fulldepth removal) to provide a smooth and even surface for repaving. Though asphalt pavement is one of the oldest urban development technologies still in use, asphalt milling is a process .

Gold mining equipment. The gold mining equipment includes: jaw crusher, hammer crusher, roller crusher, impact crusher, vertical crusher, cone crusher, ball mill, vibrating screen, spiral separator, flotation machine, mining agitation tank, ore feeder, concentrator, mine hoist, mining conveyor belt, prewatering into a ball plate, spiral chute, beneficiation shaker, washing machine and other ...

I purchased a 12"x9" hammer mill and 4''x8'' shaker table from Mt. Baker Mining and Metals because they helped me choose the right equipment regarding type and size. I have my processing plant assembled and in production. The equipment .

Pellet Mills With Automatic Roller Gap Adjustment. Yemmak Machinery Industry and Trade Inc. | Feed Milling Grinding Equipment | Pellet Mills Compared to the manuel gap adjustment pellet mills the .

Steeping Process The steeping facilitates the separation Steeping Process of the grain into its many components. In the wet milling process, steeping is the process where the grain is first soaked or "steeped" in water and dilute sulfurous acid for 2436 hours. Steep tanks may hold from to 458 cubic meters (m3) (2,000 to 13,000 bushels ...

Supply high quality biomass, grain and oil processing equipment with compecitive price! Pellet making machine, briquette press, oil milling and four milling plant.

Hosokawa Micron provides the solids and bulk handling industry with process equipment for the agglomeration of fine powders and particles, also called wet granulation or particle size enlargement. .

911MPE has small gold mining equipment for sale and more specifically mineral processing equipment is best used in small scale extractive metallurgy operations operated by small miners or hobbyist prospectors and mining fanatics. 911MPE'' offers gold mining equipment as well as processing equipment applicable to most any base metals: copper, lead, zinc, nickel, tin, tungsten .

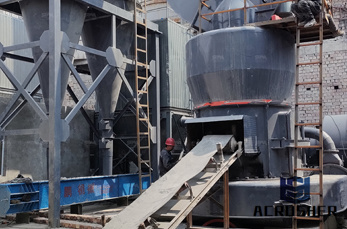

The main component of wet overflow ball mill is a cylinder with bigger diameter and smaller length which is revolved by transmitting machinery. Materials are put in cylinder through the feed opening and then thoroughly grinded. The falling course of iron balls and ores can produce huge falling impact and autogenous is a high technological enterprise that integrated research ...

Endtoend equipment options for charging, mixing, blending, milling, wet and dry granulation, tablet presses, capsule fillers, coaters, totes and bins, and primary and secondary packaging. Solid dose pharmaceutical manufacturing equipment is used in handling, granulation, tableting, capsule filling, capsule banding, checkweighing, coating ...

Small ceramic, glass or metal beads are agitated inside the mill chamber to aid particle size reduction through impact and energy input while the dispersion is pumped through the mill. Bead mills are one of the most effective methods for processing fine particles into submicron or even nanometer size range.

Ball milling is a size reduction technique that uses media in a rotating cylindrical chamber to mill materials to a fine powder. As the chamber rotates, the media is lifted up on the rising side and then cascades down from near the top of the chamber.

Enzymatic corn wet milling: engineering process and cost model. Jan 21, 2009 BACKGROUND: Enzymatic corn wet milling (Emilling) is a process wet milling companies, industry experts and equipment suppliers. Get Price; Used Mining Process Plants for Sale: Gold Mineral Mills .

wet milling process equipment for sale nkozihomcoza. kuwait wet milling process equipment for sale Corn wet milling is the process Tate Lyle We have a network of corn wet milling plants in the USA and Europe Read how we derive products from maize here Chat Online Dairy Milk analysis see analysis methods and equipment from FOSS .

WhatsApp)

WhatsApp)