Failure analysis of coal pulverizer mill shaft | Request PDF

Failure of a ball and race type coal pulverizer mill shaft has been analysed. It was found that the shaft, made of EN 25 steel, failed by fatigue.

WhatsApp)

WhatsApp)

Failure of a ball and race type coal pulverizer mill shaft has been analysed. It was found that the shaft, made of EN 25 steel, failed by fatigue.

coal pulverizer. This paper discusses the engineering analysis and actual implementation of a coal pulverizer upgrade at City Utilities of Springfield, James River Power Station in order to burn PRB coal. ... on the mill shaft in the fan section acts as primary air fan to transport the pulverized coal .

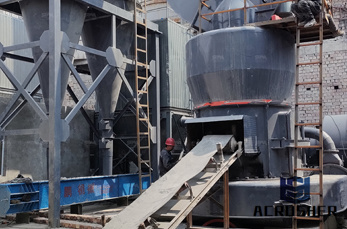

types of coal pulverizers . type of coal pulverizer . roller type coal pulverizers . Pulverizer Wikipedia. A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for combustion in the steamgenerating furnaces of .

Failure of a ball and race type coal pulverizer mill shaft has been analysed. It was found that the shaft, made of EN 25 steel, failed by fatigue. The fatigue cracks originated from the keyway area, unusually from the top edge. The presence of elongated manganese sulphide inclusions due to improper heat treatment had reduced the ductility and CVN toughness of the material, and thus made the ...

This article describes in detail the approach and root cause for failure of pinion shafts used in bowl mills of thermal power plants. • This analysis clearly indicated that ceasing of the movement of the bowl mill segment all of a sudden due to hard, rocky lumps was the main cause for failure. •

Apr 13, 2013· coal mill pulverizer, coal grinding mill, coal grinding machine, coal pulverizer equipment contains ball mill,vertical mill for coalfired power plant. bull ring segments in coal mills pictures | Mobile Crusher .

Failure Analysis Of Coal Pulverizer Mill Shaft Request PDF. Request pdf on researchgate failure analysis of coal pulverizer mill shaft failure of a ball and race type coal pulverizer mill shaft has been analysedt was found that the shaft, made of en 25 steel, failed by fatiguehe fatigue. Pulverizer Uses In Rolling Mill

Coal pulverizers. Coal pulverizers are essentially volumetric devices, because the density of coal is fairly constant, are rated in mass units of tons/hr. A pulverizer accepts a volume of material to be pulverized which is dependent on the physical dimensions of the mill and the ability of coal to pass through the coal pulverizing system.

to find out screen analysis from pulverizer. design and analysis of a horizontal shaft impact crusher ethesis. The grinding screen is also designed for optimal output from the crusher A model is also considered for the horizontal shaft impact crusher so as to find out the. ... Get price. coal mill pulverizer in thermal power plants authorstream ...

Failure analysis of coal pulverizer mill shaft ScienceDirect. Failure of a ball and race type coal pulverizer mill shaft has been analysed. It was found that the shaft, made of EN 25 steel, failed by fatigue. The fatigue cracks originated from the keyway area, unusually from the top edge.

MILLS. American Pulverizer is guaranteed to have the right mill for any size application. We are a true singlesource supplier with inhouse fabrication, machining, and assembly.

coal mill motor and shaft power. Improving Coal Pulverizer Performance and Reliability Power. ... For example, a pulverizer mill is used to pulverize coal for combustion in the steamgenerating furnaces of fossil fuel power plants. Boiler auxillaries in a coal fired power plant SlideShare.

Dec 01, 2003· Failure of a ball and race type coal pulverizer mill shaft has been analysed. It was found that the shaft, made of EN 25 steel, failed by fatigue. The fatigue cracks originated from the keyway area, unusually from the top edge. The presence of elongated manganese sulphide inclusions due to improper heat treatment had reduced the ductility and CVN toughness of the material, and thus made the ...

Failure of a ball and race type coal pulverizer mill shaft has been analysed. It was found that the shaft, made of EN 25 steel, failed by fatigue. The fatigue cracks originated from the keyway area, unusually from the top edge.

Failure analysis of coal pulverizer mill shaft ScienceDirect. Failure of a ball and race type coal pulverizer mill shaft has been analysed It was found that the shaft, made of EN 25 steel, failed by fatigue The fatigue cracks originated from the keyway area, unusually from the top edge

Failure analysis of coal pulverizer mill shaft ScienceDirect. Failure of a ball and race type coal pulverizer mill shaft has been analysed It was found that the shaft, made of EN 25 steel, failed by fatigue The fatigue cracks originated from the keyway area, unusually from the top edge.

Failure analysis of coal pulverizer mill shaft . Failure of a ball and race type coal pulverizer mill shaft has been analysed. It was found that the shaft, made of EN 25 steel, failed by fatigue. Get help online. coal hammer mill torque curve . Compound Crusher Related News . Machinery Manufacturers supply Crusher,Jaw Crusher,Impact ...

May 22, 2017· Recent failures of pulverizing wheels in fan mills of a steam turbine power plant show that the dovetailgroove area of the main components (the .

Failure analysis of coal pulverizer mill shaft

ball type coal mill animation – Failure analysis of coal pulverizer mill shaft – . Failure of a ball and race type coal pulverizer mill shaft has been analysed. It was found that the shaft, .

Failure analysis of coal pulverizer mill shaft ScienceDirect. coal pulverizer pdf:Failure of a ball and race type coal pulverizer mill shaft has been analysed It was found that the shaft made of EN 25 steel failed by fatigue The fatigue cracks originated from the keyway area unusually from the top edge.

failure analysis of coal pulverizer mill shaft request pdf . the failure analysis results of coal mill vertical shaft used in thermal power plant as carried out in a case study, will be available to the designer and manufacturer, besides the users and the experts, through the emaintenance system.

A Dynamic Analysis System Based on Component Displacement can be Useful in Improving Pulverizer operation and reducing maintenance costs. Such a system has been applied on coal pulverizers at a ...

Coal Pulverizers. RPM Associates manufactures and rebuilds coal pulverizer parts for Combustion Engineering, Foster Wheeler, Babcock Wilcox, and Alstom bowl mills. Our mill body wear liners, deflector liners, journal liners, and pulverizer rolls are engineered to offer the longest wear life with the lowest risk of catastrophic failure.

WhatsApp)

WhatsApp)