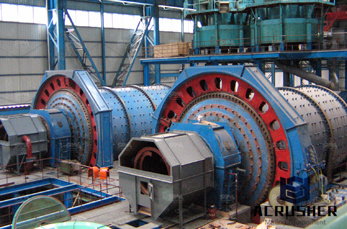

Wet Ball Mills Grate Discharge Type | Crusher Mills, Cone ...

Grate Discharge Ball MillGrate Discharge Ball Mill . Choose Quality Grate Discharge Ball Mill Manufacturers, Suppliers, Exporters at . Grate type ball mill for the wet or dry materials.

WhatsApp)

WhatsApp)

Grate Discharge Ball MillGrate Discharge Ball Mill . Choose Quality Grate Discharge Ball Mill Manufacturers, Suppliers, Exporters at . Grate type ball mill for the wet or dry materials.

Energy Saving Ball mill [ Capacity ]: –90 t/h [ Applicable Material ]: Ball mill is key equipment for grinding materials after crushing process. It is used to grind kinds of materials into fine powder 2075micrometer. Based on discharging type, It could be grate type,overflow type etc.

Jun 12, 2015· Overflow Discharge Ball Mill in Operation in a RockPhosphate Processing Plant. For more videos related to Mineral Processing visit my YouTube channel : http...

Grate Discharge Ball Mill / Bauxite Ball Mill / Powder Grinding Mill, Find Complete Details about Grate Discharge Ball Mill / Bauxite Ball Mill / Powder Grinding Mill,Grate Discharge Ball Mill,Bauxite Ball Mill,Powder Grinding Mill from Mine Mill Supplier or ManufacturerZhengzhou Hengxing Heavy Equipment Co., Ltd.

Nov 18, 2008· 1. Introduction Ball mill is an efficient tool for grinding many materials into fine powder. The ball mill is used to grind many kinds of row materials. There are two ways of grinding: the dry process and the wet process. It can be divided into tubular type and flowing type according to different forms of discharging material.

The Overflow Discharge mill is best suited for fine grinding to 75 – 106 microns. ... For overflow ball mills, the charge should not exceed 45% of the mill volume . For grate discharge mills, the charge should occupy about 50% of the mill volume . ... Ball Mill Size as a Replacement.

Classification of Energysaving Ball Mill: Energysaving ball mill for grinding various ores and other materials, are widely used in mineral processing, building materials and chemical industry can be divided into dry and wet grinding. According to different ways of discharge can be divided into the two typeslattice type and overflow type.

The size of ore shall not exceed 65mm and the best feed size is under 6mm. The effect in this job is better than coarse grinding. Grid ball mill consists of the shell, feeding part, discharging part, main bearing, lubricating system, driving system and other parts.

New and Used Ball Mills for Sale Savona Equipment is a new and used Ball Mill supplier ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

The mill is equipped with a discharge diaphragm at the end. This diaphragm retains the grinding media in the second chamber and allows the discharge of finely ground material. Closed Circuit Ball Mill System. Clinker, Gypsum and other desired additives are fed to the ball mill in specific proportions based on the quality requirement.

How a Grate Discharge Ball Mill Works | Mining Metallurgy. . with the ball mill discharge in a common sump and is pumped to 840mm . mill discharge chute design – Crusher South Africa The mill discharge flows into the sump through a movable chute fixed below the discharge launder.

Brief Introduction of Ball Mill Grinding: Ball mill Grinding can divide into 2 types, wet ball mill grinding and dry ball mill grinding. Ball mill grinding is a mineral processing machine for milling the materials into powders after they are crushed. It

Cement ball mill is an important fine grinding equipment. It has the characteristics of high efficiency, energy saving, environmental protection and large production capacity. In the selection of the same type of ball mills, as long as their ore f...

EXERCISE 61 Ball milling circuit using Austin''s model . D80 in the mill feed and product. Calculate the power required using Rowland''s factor for Bond work index in open . the ball mill feed and the cyclone overflow.

Ball Mill for Sale. APPROXIMATE CAPACITIES. All ball mills operate on the same principles. One of these principle is that the total weight of the charge in the millthe sum of the weight of the grinding media, the weight of the material to be ground, and any water in the mill—is a function of the percentage of the volume of the mill it occupies.

Discharge of pebbles, finer rock, ball scats and slurry from mills and its flow through trommels, and into other processing operations has strong impacts on overflow ball mill performance.

The fineness of product delivered by a ballmill, the size of feed, ball charge, and speed remaining constant, depends upon the tonnage fed, the density of the pulp (water to solids ratio), size of balls, and, when operating in closed circuit, on the efficiency of the external classifying apparatus.

I am working in a plant with single stage grinding using a ball mill we operate the mill power at around 1400KW the feed size is 20mm. we use 78mm/64mm steel balls. the ball mill is in closed circuit with classification cyclones. there are 3 cyclones and we operate 2 with a pressure of about 90KPa.

The ball mill is easy to maintain as all wear parts are manufactured from high grade materials and are easily accessible for replacement. The design of the vessel, shaft pin configuration, and ideal parameter control, make this ball mill the most efficient in today''s market.

Lab Equipment. Size Reduction. Barrel Mill; Rod/Ball Mill; Finger Crusher; Hammermill; Jaw Crusher; Lab Mill 200; Overhung Hammer Mill; Rolls Crusher; Screening. Sieve Shakers; Test Sieves; Splitting and Dividing. Jones Rifflers; Sample Splitter; Tube Divider; Mixing or Blending. MACSALAB TUMBLE MIXER; MACSALAB VBLENDER; MACSALAB CONE BLENDER ...

Apr 22, 2017· Though I didn''t worked on large scale mill but I worked on laboratory scale mill (Dry ) for determination of Bond''s work index. The following limitation/disadvantages I found: 1. Low output compared to rod mill. 2. High noise and vibration. 3. Non...

A wide variety of ball mill discharge options are available to you, There are 373 ball mill discharge suppliers, mainly located in Asia. The top supplying country or region is China, which supply of ball mill discharge respectively. Ball mill discharge products are most popular in .

Cylindrical Ball Mills. The only cylindrical ball mills in common use are those of the grate discharge type, the most important being the Marcy and the AllisChalmers mills. Fig. 10 illustrates the construction of the Marcy Ball Mill. The cylindrical shell and the feed and discharge .

Ball milling is a size reduction technique that uses media in a rotating cylindrical chamber to mill materials to a fine powder. As the chamber rotates, the media is lifted up on the rising side and then cascades down from near the top of the chamber.

WhatsApp)

WhatsApp)