(PDF) A comparison of wear rates of ball mill grinding media

The ball mill abrasion test (BMAT) promises to offer accurate prediction of relative service lives of wearresistant alloys for liners and grinding media in mineral grinding environments.

WhatsApp)

WhatsApp)

The ball mill abrasion test (BMAT) promises to offer accurate prediction of relative service lives of wearresistant alloys for liners and grinding media in mineral grinding environments.

Comparisons on the morphology, size, type and distribution of carbides were carried through optical microscopy, SEM and XRD. Hardness testing was employed at room temperature with the purpose of correlate to wear behavior. A laboratory pilotplant ballmill set with a batch of ore was utilized in order to evaluate the abrasive wear resistance.

In Australia, the LA abrasion method is available in the Australian Standards (AS ), whereas other standards, such as ASTM C131/C131M, may be used in other parts of the world. Los Angeles abrasion. The LA abrasion test is a standard method for measuring the abrasion resistance of unbound granular materials (Kraman et al., 2010).

Fourthane Silver Line. This is a polymeric putty with high resistance to abrasion, impact and shear. Especially design for SAG mills ball mills and other mass scale applications.

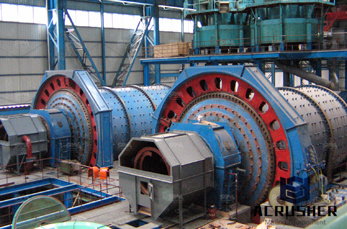

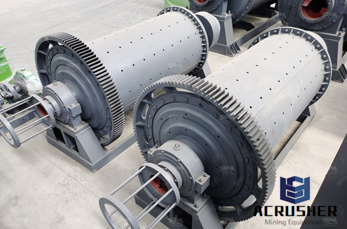

2019 Zhongde Mining Grinding Ball Mill For Ore,Cement,Gypsum For Sale, Find Complete Details about 2019 Zhongde Mining Grinding Ball Mill For Ore,Cement,Gypsum For Sale,High Safety Ball Mill For Sale,High Abrasion Resistance Ball Mill Low Price,Hot Sale Cement Grinding Ball Mill from Mine Mill Supplier or ManufacturerLuoyang Zhongde Heavy Industries Co., Ltd.

Alumina mill ball is widely used in industries of ceramics, cements, paint, dyeing, chemicals, pharmaceuticals, coating and mining. It has advantages of high hardness, good toughness, high density, good erosion resistance, regular shape etc.

ZIBO QIMINGXIG NEW MATERIAL CO.,LTD. was founded by Hejun in 1997. QIMINGXING has grown quickly to become one of the leading supplier for ceramic grinding media and powder grinding machine in our range. Our customers have embraced the quality of our products, direct and indirect cost savings, and our commitment to excellence in a National Hightech enterprise, in 2015 ...

Abrasion resistance: good Suitable for: soft to mediumhard samples Detailed information about the material you will find in the element analysis. The grinding ball made of agate with 50 mm dia. is recommended as standard.

About. Xinhai provides Turnkey Solution for Mineral Processing Plant, including design and research, machine manufacturing, equipment procurement, management service, mine operation, mine materials procurement management.

Corrosion and abrasion resistant, tough and durable, NITRONIC 30 is the stainless steel for your abrasive needs. Ball mill tests have shown that many application standards, such as AR 500 suffer six to seven times as much metal loss as NITRONIC 30. Economical, low alloy, corrosion resistant, abrasion resistant stainless steel.

Mar 16, 2018· Medium, low alloy wearresistant steel usually contains chemical elements are silicon, manganese, chromium, molybdenum, vanadium, tungsten, nickel, titanium, boron, copper, rare earth and so on. Many large and mediumsized US ball mill liner are made of chrome molybdenum silicon or chrome molybdenum steel.

Using the Bond Index test procedures it is possible to calculate crushing / abrasion behavior of mineral samples. This knowledge is essential to define the required ball mill layout and production capacity. In order to perform the Bond Index Test successfully it is necessary to use precrushed sample material as defined below: Module Ball Mill

The configuration of the liner of ball mill is of great significance to the ball mill. Low energy consumption, rubber lining quality is light, reduce the cylinder quality, thereby reducing the load of the motor, saving electricity, that is, reduce the cost. With high abrasion resistance and impact resistance, the rubber lining plate adopts ...

Product usage of our BD709 ball mill end caps wear abrasion impact resistant epoxy compound coating: BD709 ball mill end cover anti wear abrasion impact resistant protective coating is the high performance wear impact resistant polymerization material compounded by high performance

Zoneding High Abrasion Resistance And High Grinding Ball Mill. A verified cn gold supplier on mineral processing capacity of worlds largest ball milllanetary ball mill pricemall grinding quartz lmestone gold ore beneficiation laboratory planetary ball mill price for sale in powdery zoneding high abrasion resistance and world advanced technology planetary grinding ball mill price for sale et price.

> Abrasion resistance (usually desired property of this material) increases with carbon content, but toughness decreases > Various grades class I type A abrasion resistant; class I type B toughness > Applications: Because of low cost, used primarily in mining applications as ball mill liners and grinding balls Typical microstructure of class 1

The corrosion resistance of this type of steel is due to a very thin, not visible oxidic protective film which is formed when the chrome content is >12 %. The corrosion resistance increases with the chrome content. However, if the chrome content is more than 20 %, the steel loses its hardenability and thus its wear resistance.

Mar 15, 2016· Ball Mill Crushing and Grinding Working Principles 911 Metallurgy Corp. ... results from striking or compression by a steel ball, in a mill. ... is the abrasion and wear that result from rubbing ...

Ball milling is one of the few unit operations that actual improve in performance and efficiency with increasing size. The ABBE Slice Mill is the same as the product mill and can replicate all mill operating parameters but with very little product. Materials: Abrasion Resistant Steel, Stainless Steel, Polyurethane or Rubber Lined.

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles and stainless steel balls.

The ball mill has many outstanding features, such as high grinding ratio, high adaptability of material and good abrasion resistance etc. And the ball mill has the advantages of .

BALL MILL METHOD FOR DETERMINING THE DISINTEGRATION OF FLEXIBLE BASE MATERIAL TXDOT DESIGNATION: TEX116E CONSTRUCTION DIVISION 3 – 5 LAST REVIEWED: SEPTEMBER 2014 water for one hour. If 2 L ( gal.) of water do not fully cover the sample, use the smallest amount of water possible to do so. Note 1—Use the dry sieve analysis as a rough check for specification .

Founded in 2002 year, Pingxiang Ceramics Co.,Ltd dedicates to be an expert of manufacturing wear resistant alumina ceramic lining products and wear protection solution provider. The wear abrasion resistant ceramics output is 5000ton years. The major raw material alumina powder is imported from Australia and France.

Although the true wear test of a grinding ball is its life in a real ball mill, the laboratory tests of impact and abrasion may serve as a guide to expected ball life. The two most significant differences found among the commercial balls were the number of impacts to breakage and the impactspalling rate.

WhatsApp)

WhatsApp)