Bead Mill YouTube

Jul 03, 2015· DIY how to kill crabgrass. My crabgrass is not dying. How to prevent and control crabgrass Duration: 10:53. Pest and Lawn Ginja 1,016,713 views

WhatsApp)

WhatsApp)

Jul 03, 2015· DIY how to kill crabgrass. My crabgrass is not dying. How to prevent and control crabgrass Duration: 10:53. Pest and Lawn Ginja 1,016,713 views

continuously discharges products out of the mill by centrifugal force. (Fig. 6) HSA Attritors generally operate from RPM using grinding beads from 13mm. This combination of high velocity and increased grinding media surface area insure much finer grind of the processed material. The HSA Attritor is generally used in a continuous mode.

This will normally improve the dispersion. Smaller and/or harder beads ( zircon oxide or steel) can also improve the dispersion result. Further, the bead charge can be increased to about 80%. In order to operate the bead mill economically, dispersion should be made with as much solid matter as possible.

This unit of competency covers the skills and knowledge required to operate wet milling equipment and its ancillary equipment. Wet milling equipment is used in plants that manufacture paint and other materials. The wet milling equipment may be vertical or horizontal mills and may incorporate rolls, balls or beads as the milling medium.

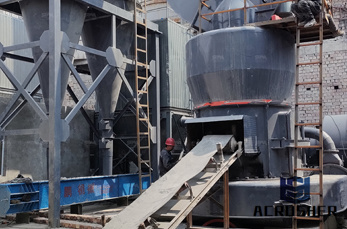

For decades, agitator bead mills from NETZSCH have been successfully employed in a broad range of industries for the grinding and dispersing of suspended solids. This globallyproven technology from wet applications was now transferred to dry grinding: The NETZSCH SpheRho ® is an agitator bead mill with unique product advantages.

Dec 07, 2007· Mill Spring, NC. comes naturally said: ... Not to mention the glass beads on a concrete floor are pretty slick.:eek1 I think you can use any granular material. I know they use baking soda in some applications and walnut shells as mentioned. The media will depend on what you want to do. Some media will peen the surface and increase strength ...

Numerous products can not easily be used for further use due to their grain distribution after a production or grinding process. The supplementary classifying for the production of the exact grain size is necessary to get or maximize the necessary characteristics of the product.

Mar 05, 2008· Lovely tutorial! Almost exactly how I make my felted beads...I like how you roll the roving up though in the beginning. I roll very gently on bubble wrap for a little bit before switching to my hands. The one issue I always have is making the beads the same size over and over .

Whether you wish to make rock collecting or lapidary your work or your hobby, you''ll need to learn how to grind and polish stones. Although this process might sound like it requires exertion, a rock tumbler usually does most of the work. As you tumble the stones with progressively finer .

Dry Grinder. is designed to crush materials to micrometer size. The high speed rotating blades can produce 200 mesh or fiber (below 74μm) powder, and discharge via centrifugal force. In addition, with a continuous feeding device and nonfilter device it does not .

Oct 04, 2011· Wal Engineers Liter Bead Mill comprised with mm high density Zirconium Beads and 15 hp motor. Single pass or circulation further information contact at or ...

Bead mills are available in various sizes and configurations from the Mickle shaker which has a maximum volume of about 40 ml to continuous process equipment capable of handling up to 200 Kg wet yeast or 20 Kg wet bacteria each hour. The bead mills that have been studied in most detail are the DynoMill and the NetschMolinex agitator, both of ...

Nov 21, 2012· DEM simulation of bead motion during wet bead milling using an enlarged particle model. ... It has not been applied to a bead mill. As described in this paper, a simulation model was developed for numerous bead motions and it applies for the bead mill. The model validity is investigated by comparing the bead motion obtained from the simulation ...

They have shafts with arms and run at RPMs from 100 to 650 and can be used for wet or dry grinding. The Model HDDM01 is designed for small media ranging from .25mm (or smaller) to 2mm. These models have shafts with special UP Delta Discs (similar to those used on the Union Process DMQX Bead Mill) and run at RPMs of 1000 to 4200.

Oct 30, 2015· Titanium is a metal that requires wet milling. Cobalt chromium is generally milled in a wet mill but may in certain instances be milled dry. Wet Milling. Wet mills use distilled water with an additive that works as a coolant for the tools and material that is being milled. Wet mills need to be cleaned on a regular basis to remove the material ...

> Wet Milling, Comminution and Emulsifying Equipment > Bead Mills. Bead Mills. Horizontal Bead Mill. These mills use small grinding media to act against cells. The DYNO®MILL uses agitator discs inside an enclosed chamber to whip the beads into a highshear frenzy which then collide with the cells and produce breakage.

The multifunctional laboratory mill LabStar enables scientific academic work even at difficult research and development tasks and convinces by easy handling. The laboratory mill LabStar is the smallest grinding unit of NETZSCHFeinmltechnik that enables an exact scaleup to comparable production machines.

NETZSCH Premier Technologies, LLC is the North American subsidiary of the globally operated group of NETZSCH companies. NETZSCH is a leading manufacturer of wet grinding and dispersing machinery, including media milling, dispersing and deaerating from lab research to fullscale production in the following applications:

Currently, the pharmaceutical industry faces considerable challenges associated with the increasing number of poorly watersoluble drugs coming through the drug discovery pipeline, .Despite promising pharmacological activity, many of these drug candidates fall under class II of the Biopharmaceutics Classification System (BCS), characterized by high membrane permeability but low aqueous ...

Jun 11, 2003· Bead Mills reduce particles to submicron sizes. Laboratory and Research Supplies and Equipment Cold Milling Machine efficiently grinds flax seed. Laboratory and Research Supplies and Equipment Solid Ceramic End Mill comes in 4 or 6fluted versions. Laboratory and Research Supplies and Equipment Centrifugal Impact Mill controls particle sizes.

If you want to know where your food comes from there is no better way than to mill it yourself in your own home. With a NutriMill grain mill, you will not only reap all the flavor and health benefits of whole grain nutrition, your budget will also reap the benefits of taking the .

Do Not use larger vessels (Mason jars, etc.) with the BeadBeater. These containers do not achieve good homogenization and, if made of glass, may break and cause injury. BioSpec Products has extensive experience with the use of continuous beadmills capable of .

Energy is transferred from the disk to the fluid in the mill and the product is sheared by the surface of the media rather than by the disks. Media is uniformly distributed and there is little physical attrition. Some advantages of horizontal mills in wet milling incl. Highly efficient use of small amounts of media

May 01, 2014· That means the lab mill and the production mill were not from the same mill series. To do this, a lot of experience is necessary. This is possible when a mill user has many different products, and when the user generates a lot of scale up data with these products. A Typical Multifunctional Agitated Lab Bead Mill

WhatsApp)

WhatsApp)