(PDF) COAL MINING METHODS ResearchGate

coal mining methods, ... Auger mining uses largediameter drills mounted on m obile equipment to bore into a coal seam. ... While extraction of all the coal in a pillar is a desirable ...

WhatsApp)

WhatsApp)

coal mining methods, ... Auger mining uses largediameter drills mounted on m obile equipment to bore into a coal seam. ... While extraction of all the coal in a pillar is a desirable ...

The top three occupations in the Coal mining Industry Group are Mining machine operators, Firstline supervisors of construction trades extraction workers, Construction equipment operators except paving, surfacing, tamping equipment operators, Miscellaneous extraction workers, including roof bolters helpers, and Driver/sales workers truck drivers.

Closeup. Underground and Surface Mines . Coal was the fuel that stoked the Industrial Revolution in the 19 th century. Extracting coal from underground or openpit mines continues to be a vital part of the world economy today.

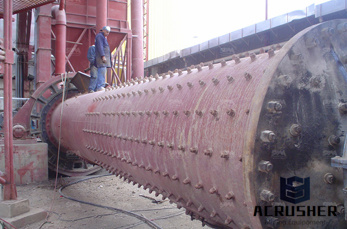

Longwall mining. In the longwall mining method, mine development is carried out in such a manner that large blocks of coal, usually 100 to 300 metres wide and 1,000 to 3,000 metres long, are available for complete extraction (see photograph).A block of coal is extracted in slices, the dimensions of which are fixed by the height of coal extracted, the width of the longwall face, and the ...

Due to growth in surface mining and improved mining technology, the amount of coal produced by one miner in one hour has more than tripled since 1978. Surface mining is used to produce most of the coal in the because it is less expensive than underground mining. Surface mining can be used when the coal is buried less than 200 feet underground.

Mining Cost Service, Mine Mill Equipment Estimator''s Guide: all the data you need for doing mine cost estimates. ... Industry Standard for Mining Cost Estimating Specializing in Cost Models, Equipment Costs, Labor Costs, Supply Costs, Smelting and Mine Development Costs ... The guide provides coalspecific estimating information similar to ...

When coal has been extracted from the area, the roof is allowed to collapse. Over 75% of the coal in the deposit can be extracted from panels of coal that can extend 3km through the coal seam. Technological advancements have made coal mining today more productive than it has ever been.

Choosing a mining method. The various methods of mining a coal seam can be classified under two headings, surface mining and underground mining. Surface and underground coal mining are broad activities that incorporate numerous variations in equipment and methods, and the choice of which method to use in extracting a coal seam depends on many technological, economic, and social factors.

Aug 30, 2012· The other major form of underground coal extraction is longwall mining. In longwall mines, equipment used in Room and Pillar mining is used to develop two or three parallel entries in a coal seam. The longwall mine entries or headings are usually separated by several hundred feet of solid coal.

Recommendation: There should be renewed support for advanced coal mining and processing research and development to optimize use of the nation''s coal resources by increasing the amount of coal that is economically minable through technological advances .

The global mining equipment market size was valued at USD billion in 2017 and is anticipated to record a CAGR of % during the forecast period. Growing drilling and exploration activities across the globe are projected to drive the market over the coming years

In surface mining, the ground covering the coal seam (the overburden) is first removed to expose the coal seam for extraction. The elements of a surface mining operation are (1) topsoil removal and storage for later use, (2) drilling and blasting the strata overlying the coal seam, (3) loading and ...

Modern Coal Related Technology Mining Equipment ... Reclamation: Safety Related Equipment: End Uses of Coal: Mining Related Equipment . Equipment used in the Mining Industry today. Surveying; Complex Underground Equipment ... Complex surface mining equipment is used directly or as support in the mineral extraction process: Draglines; Shovels ...

1 The private mining, quarrying, and oil and gas extraction sector industry sector includes such subsectors as oil and gas extraction, coal mining, metal ore mining, nonmetallic mineral mining and quarrying, and support activities for mining. The IIF program uses the North American Industry Classification System (NAICS) to define industry. From 2003 to 2008 the IIF .

PILLAR EXTRACTION USING CONTINUOUS MINERS. Overview. Now that longwall equipment has been developed to a stage where it is able to cope with most conditions satisfactorily, longwall mining is the most widely used method of secondary extraction. However, there are still mines and occasions where longwall mining is not suitable

Dec 27, 2018· Each segment requires the use of specific equipment, but there are several types of mining equipment that are used throughout the industry. This equipment includes excavators, draglines, drills, roof bolters, continuous miners, longwall miners, rock dusters, shuttle cars and scoops.

Get more details on this report Request Free Sample PDF In 2017, surface mining machinery market accounted for over 30% of the overall industry share. These machines are experiencing a high adoption due to the rise in demand for extraction of minerals such as nonmetallic ore, metallic ore, and coal.

Coal Mining Methods ... Longwall Room and Pillar Mining Longwall mining and roomandpillar mining are the two basic methods of mining coal underground, with roomandpillar being the traditional method in the United States. Both ... longwall equipment. Extraction by Longwall Mining After the longwall panel has been blocked out by entries, it ...

Coal mining is the process of extracting coal from the ground. Coal is valued for its energy content, and, since the 1880s, has been widely used to generate electricity. Steel and cement industries use coal as a fuel for extraction of iron from iron ore and for cement production.

The two mining methods used in coal extraction are surface "Open Pit" mining and Underground mining. Simply put, surface mining is peeling back the earth and collecting coal near the surface. Whereas, underground mining requires tunneling and building shafts. The mining method chosen by companies depends on the coal deposit being extracted.

Coal is an abundant fuel source that is relatively inexpensive to produce and convert to useful energy. However, producing and using coal affects the environment. Effects of coal mining. Surface mines (sometimes called strip mines) were the source of about 65% of the coal mined

Coal extraction and mining equipment coal mining physical extraction of coal resources to yield coal also the business of exploring for developing mining and transporting coal in any form strip mining is the process in which the overburden earth and rock material overlying the coal is removed to expose a coal seam.

Mining is the extraction of valuable minerals or other geological materials from the Earth, usually from an ore body, lode, vein, seam, reef or placer deposits form a mineralized package that is of economic interest to the miner. Ores recovered by mining include metals, coal, oil shale, gemstones, limestone, chalk, dimension stone, rock salt, potash, gravel, and clay.

human resources at an underground coal mine in Grafton, West ia. "The skills you need to play video games are the types of skills you need to operate our equipment." This article describes occupations in the mining, oil, and gas extraction industry. It does not include occupations related to the processing or distribution of these ...

WhatsApp)

WhatsApp)