steel mill scale pit scale removal

steel mill scale pit scale removal Grinding Mill China. steel mill scale pit scale removal Posted at: May 9, 2013 [ 47 6586 Ratings ], where heavy greases and oils accumulate in the steelmill scale pit...

WhatsApp)

WhatsApp)

steel mill scale pit scale removal Grinding Mill China. steel mill scale pit scale removal Posted at: May 9, 2013 [ 47 6586 Ratings ], where heavy greases and oils accumulate in the steelmill scale pit...

steel mill scale pit scale removal christientendamantieknl. Mill Scale is produced in Hot Rolling operations in the iron and steel industry, in which scale is removed from the surface of hot steel through spray water and contact with the rolls that effect size reduction The scale thus removed typically discharges with the water used for ...

Aug 16, 2016· I recently picked up some steel at my local supplier. It had a thick layer of mill scale on it. A task that normally took 3045 seconds to complete became a 15 minute ordeal. Having to soak it in ...

I rarely remove the mill scale for most of the things I build, and more often than not, it''s just for the weld. What are you making? Another idea would be emery cloth and wrap it around the round stock and pull back and forth. This would be a more manual process, but would follow the curve for half of the crosssectional circumference at a time.

In a rolling mill where the steel will be stretched and squished the mill scale will first be removed mostly by water jets, or by sand blasting in some shops or by vibrating rolls in others and the mill scale will fall into a pit below the equipment where it will also be joined by rolling mill .

removal of mill scale from a pit ediliziacostamarco . The descaling water and the cooling water wash the mill scale away from the steel surfaces, flow with the mill scale into the flumes underneath the rolling lines, run at a high speed in the flumes and eventually are discharged into the deep and wide mill scale pits.

Jun 10, 2017· Harold (and possibly others) recommended vinegar to remove mill scale from hotrolled steel. I decided to give it a shot. Ordinarily, I would use abrasives or electrolysis, but abrasives don''t do well with the magnetite in scale (Mohr hardness +), and electrolysis tends to put magnetite ON things.

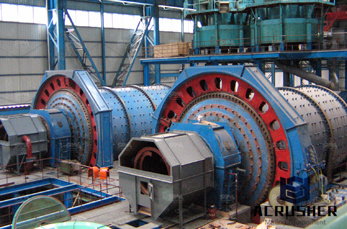

About Our Company. Professional mining equipment manufacturers. steel mill scale pit design Development of a water treatment plant for a rollingmill Official FullText PaperPDF Development of a water treatment plant for a rollingmill trainsteel mill scale pit design,mill scale in steel sand washing machineAbout steel mill scale pit designrelated information inside the mill .

steel mill scale water pit . What exactly is Mill Scale and what is done about it. In a rolling mill where the steel will be stretched and squished the mill scale will first be removed mostly by water jets, or by sand blasting in some shops or by vibrating rolls in others and the mill scale will fall into a pit below the equipment where it will also be joined by rolling mill lubricants and ...

Aug 20, 2007· Removal of mill scale is very important in virtually all welding applications. I have a great demo on the effect that mill scale has on a weld. Take a piece of hot rolled steel plate or flat bar, ~8" long. Thoroughly grind 1/2 of the surface to remove all mill scale.

Mill scale is found on all hotrolled steel products unless processed in a .... plates are always painted, and to properly paint them requires removal of mill scale. .... rolls in others and the mill scale will fall into a pit below the equipment where it...

HAUGEN System AB Specific steel mill clean out applications. Removal of raw material spills from conveyor systems to blast furnace storage bins, from skip pits and around scale car tracks; clean up of flue dust conveying...

Dec 20, 2013· MILL SCALE OPERATION AT JSW BELLARY HOT STRIP MILL SCALE PIT FLUDCON. Loading... Unsubscribe from FLUDCON? ... Four Ways to Remove MILL SCALE Duration: 15:19. 104,069 views.

Mill scale is thus a boon for a while until its coating breaks due to handling of the steel product or due to any other mechanical cause. Mill scale becomes a nuisance when the steel is to be processed. Any paint applied over it is wasted, since it will come off with the scale as moistureladen air gets under it.

Jun 29, 2019· I have read that soaking it in white vinegar overnight will remove or at least remove a lot of the mill scale and would be easier to finish removing the leftover mill scale. From what I understand it will need to be neutralized also, but a good rinse with fresh water and then with baking soda/water.

Everyone should know by now that you need to remove mill scale prior to welding. Unfortunately, it is one of those awful tasks that nobody wants to do. Why? Because mill scale is a pain to get off and an even bigger pain to get off without impacting the material beneath it. Here''s Four Ways to Remove Mill Scale..

Mill scale is a tough layer of iron oxides and magnetite which coats the surface of hot rolled steel. It is necessary to remove mill scale before welding or painting can occur, but the process is usually difficult and time consuming. Our process eliminates mill scale quickly and efficiently, leaving a white metal finish.

This post discusses the role of mill scale in the steel production and coating process, including the fastest way to remove mill scale from surfaces. Identifying Mill Scale. Mill scale (often known simply as ''scale'') refers to the thin, flaky texture that forms on the outer surface of hotrolled iron oxides and metals.

steel mill scale pit scale removal tube expanders, tube tools for heat exchangers boilers. removal tools. The selection of removal tools will allow you to remove any size or type of tube from a vessel.

Mill Scale Removal Made Easy! Dustless Blasting. Mill scale is a tough layer of iron oxides and magnetite which coats the surface of hot rolled steel. It is necessary to remove mill scale before welding or painting can occur, but the process is usually difficult and time consuming.

Apr 06, 2019· Mill Scale on the joint of the mild steel you''re planning to weld is an impurity on the surface of your weld. Along with other possible impurities such as oil, paint and rust, it is best to remove the mill scale before you weld.

Hi guys, Maybe you have a slick way of removing mill scale from hot rolled shapes, typically bar stock. I have tried wire wheels, 36 grit flap wheels on 41/2" angle grinder and 36 grit Roloc discs on a 2" air angle grinder.

May 10, 2013· Top secret formula for removal of mill scale on hr steel!!! Got this formula from the Home Shop Machinist Forum to an inquiry I made about how this stuff can tear up tooling. If you have ever tried to sand it, grind it, blast it, machine it, or otherwise try to get this stuff off you know it is tougher than a pigs nose!

PROJECT PROFILE FOR HIGH RATE FILTERS FOR MILL SCALE REMOVAL PROJECT DETAILS: Mill scale, often shortened to just scale, is the flaky surface of hot rolled steel, iron oxides. Mill scale is formed on the outer surfaces of plates, sheets or profiles when they are being produced by rolling red hot iron or steel billets in rolling mills.

WhatsApp)

WhatsApp)