Wet Milling Equipment | Products Suppliers | Engineering360

Dry milling may also be preferred over wet milling due to incompatibility between the processing solvent and the available wet milling equipment, such as when the process .

WhatsApp)

WhatsApp)

Dry milling may also be preferred over wet milling due to incompatibility between the processing solvent and the available wet milling equipment, such as when the process .

corn wet milling process was obtained from various technical sources including commercial wet milling companies, industry experts and equipment suppliers. 2. Process model description The conventional wet milling process includes many steps for the recovery and purification of starch and all coproducts (germ, gluten meal, and corn gluten feed).

Product feeding and dosing are easier with wet milling than with a dry process. Wet milling is successfully used for many applications in the pharmaceutical industry because it works well with API (active pharmaceutical ingredients). IKA dispersing machines can be directly integrated into the substances'' synthesis process.

Probst Class Machines for industrial process technology. More than any other machinery producer, PUC is a name that stands for longevity in connection with emulsifying, dispersing and suspending machinery and equipment. In industry, the PUC name has been synonymous with .

Cone milling is one of the most common methods of milling in the pharmaceutical, food, chemical and associated industries. They are typically used for size reduction and deagglomeration or delumping of powders and granules.. Generally used for reducing material to a particle size as low as 180µm (80 mesh) they produce less dust and heat than alternative forms of milling.

flour milling machine,maize flour milling machine is exported to many machinery is a famous manufacturer for flour milling machine, maize milling machine,wheat flour milling machine,flour milling supply flour milling machine

Rice Milling and Drying Information. Milling of Rice. During the milling stage the rice moves through a multifaceted process. When rice arrives at the mill, it is ushered through a series of sorting machines, separating the kernels, encased in an inedible hull or husk, from any debris. ... World Market Price For Rice · Monday, May 27, 2019 at ...

As the name suggests, wet milling involves size reduction of drug particles suspended in a liquid medium that may be aqueous or nonaqueous in nature. Wet milling is particularly suited for potent drugs and drugs which possess high residual moisture contents (>50% moisture) because dry milling may be problematic for drugs of this nature.

offers 369 wet milling equipment for corn products. About 48% of these are flour mill, 42% are other food processing machinery, and 3% are rice mill. A wide variety of wet milling equipment for corn options are available to you, There are 369 wet milling equipment .

Fluidquip supplies process equipment for most of the physical separation steps of the corn wet mill, whose individual processes shown on the Corn Wet Milling Process Flow Sheet are discussed in general terms below: STEEPING The corn after arriving to the plant, must be cleaned to meet the standards of the Yellow Dent #2 corn. The cleaned ...

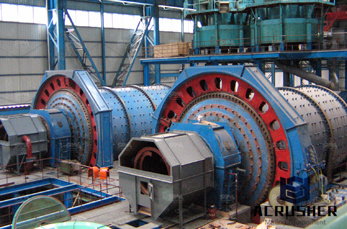

Wet milling, also called wet media milling, is a process in which particles are dispersed in a liquid by shearing, by impact or crushing, or by attrition. A mill is charged with media (small beads or spheres) and activated by a highspeed agitator shaft to separate the individual particles.

Oat and Rice Miling. ... Our range of rice milling equipment covers all the key process stages from cleaning and sorting of paddy rice to high capacity whitening and polishing lines. From single machine supply through to complete processing plants we have equipment and process knowledge to meet all client requirements.

LEASE PRICE. 590 US** ** For 60 months, OAC . Financial Services; The DGSHAPE DWX42W enables wet milling of popular glass ceramic and composite resins with high precision and accuracy. High speed production with proprietary DGSHAPE spindle Expanded 6tool Automatic Tool Changer for uninterrupted milling

Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material. The milling process requires a milling machine, workpiece, fixture, and cutter. The workpiece is a piece of preshaped material that is secured to the fixture, which itself is attached ...

In wet milling, the grain husk remains mainly complete, whereas in a dry mill it can fragment. This fragmentation can slow runoffs and cause quality problems. Because of the higher moisture content during wet milling, there is no dust produced, so explosion risks are eliminated and dust removal equipment unnecessary.

Production Process Value. If your pharmaceutical, food, chemical or personal care and cosmetics application doesn''t require the highest energy levels of a dedicated highpressure homogenizer or media mill, the Quadro® HVEmulsifier and Wet Mill offers better process value.

Wet Milling of Cereal Grains Robert L. Zipf Orlando Jones, an Englishman, was absence a pioneer whose work in 1840 founded a multimilliondollar insideindustry that touches all our daily lives. Every early ties starch producer used his process, in which an alkali Commercially,was used to recover the starch. The process worked so well that

27 corn wet milling facilities were reported to be operating in the United States. Process Description14 The corn wet milling industry has grown in its 150 years of existence into the most diversified and integrated of the grain processing industries. The corn .

The choice between wet and dry milling is, in general, unimportant in smallscale milling but is a major technical problem when largescale milling in the metallurgical industries is involved. On purely mechanical grounds it is difficult to see any great difference in fundamental principles between wet and dry milling, since dry milling may be regarded as wet milling with a fluid having the ...

From micronization services to wet milling to jaw crushing, our milling process experts will mill the material you need ... Custom Processing Services — the right particle size reduction equipment to mill the material you need: food, pigments, chemicals, ceramics, and more.

1. Principles of milling bulk solids. Milling is the action of reducing the size of particles thanks to a mechanical action. The mechanical action is submitting the particles to a stress, under the stress, some cracks will appear and subsequently the particle will be broken in different parts.

Continuous mill versions of Union Prcocess''s wet grinding Attritors offer a compact vertical design suitable for continuous production of large quantities

Jan 21, 2009· Enzymatic corn wet milling (Emilling) is a process derived from conventional wet milling for the recovery and purification of starch and coproducts using proteases to eliminate the need for sulfites and decrease the steeping time. In 2006, the total starch production in USA by conventional wet milling equaled 23 billion kilograms, including modified starches and starches used for .

Additionally, we can provide standalone machines in the 24 to 1,000t per day range, which include popular selections such as the grain precleaner, grain cleaning equipment, flour milling machine, flour processing equipment, maize processing equipment, and conveying equipment.

WhatsApp)

WhatsApp)