Vertical Mill Rocker Arm and Separator

Vertical mill pressure device is to provide the pressure roller milling parts, which consists of highpressure filling stations, hydraulic cylinder rod, accumulator etc, able to exert enough pressure roller .

WhatsApp)

WhatsApp)

Vertical mill pressure device is to provide the pressure roller milling parts, which consists of highpressure filling stations, hydraulic cylinder rod, accumulator etc, able to exert enough pressure roller .

Dec 31, 2014· LUM Ultrafine Vertical Roller Mills are used for pulverizing minerals, such as grinding quartz, feldspar, calcite, talcum, barite, fluorite, copper ore quartz, zircon sand, fly ash and coal, etc ...

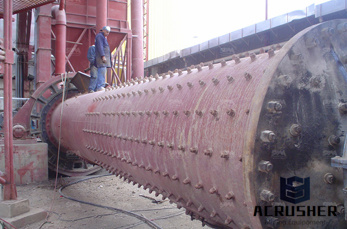

Grinding roller is the key grinding part and the core component of vertical roller mill. CHAENG manufactures vertical mill grinding roller, grinding table, roller hub, roller shell according to customers'' drawings and requirements.

ROLLER MILLS With more than 125 years of experience, Raymond is a leader ... The roller mill is an air swept vertical ringroll with an ... Plows rotating with the assembly lift feed material from the mill bottom and direct it between the rolls and the grinding ring where it is pulverized. Air enters from below the grind ring and flows upward

Vertical roller mills KTM Assembly of a mill for 150 t/h of raw meal With 4 runners in PSP''s work shop: Grinding runner with carrier Lift out of grinding runner Placement of grinding carrier in the bearings Cover of the grinding chamber Check assembly of the upper part of the mill separator Placement of grinding carrier in the bearings

Various Parts Of Vertical Roller Mills List Of Milling Machine Manufacturers | Wiki Machine. Vertical milling machine and horizontal milling machine compared to the main difference is the vertical arrangement of the spindle, in addition to the spindle layout is different, the table can be up and down, vertical milling machine with a relatively flexible milling cutter, a wider range of ...

Assembly is completed onsite. The smaller vertical mills might be only feet tall, while a large mill can stand well over 10 feet high, and create a footprint of 20 feet square or larger. Identification. A vertical milling machine''s spindle axis is aligned in a vertical manner to the machine''s bed.

Most heads are based on a Bridgeport design and have been cloned by Taiwanese and Chinese manufacturers. The WellsIndex milling head is a much more robust and durable design for heavy cutting with most components such as the spindle diameter, bearings, gears, and splines being 40% to larger than its competitors.

Add new functionality to your milling machine and keep it performing well with milling machine attachments, parts and accessories at MSC. From adapters for milling heads to risers, drawbars and spacer blocks, you''ll find everything you need.

1254 Roller Mill with folding Auger Video 1254 Double Roller Mill Video 1254 Triple with HDFY 3Point Scraper. 1254 Roller Mill with 18'' Belt Discharge Flyer Click to request More Info . Built with the operator in mind, our Roller Mills are easy to adjust, easy to operate and easy to maintain.

Overview of all of our mills . Mills for grinding cement, coal, or minerals: Christian Pfeiffer designs and builds grinding plants for many different feed materials and finished products. Our mills are as varied as the requirements of our customers. Ball mills, vertical mills, compact mills, jet mills or roller mills? Our employees are experts ...

for mills PULVERIZERS CE RAYMOND Roller Mills CE Raymond Bowl Mills CE Raymond Vertical Mills CE Raymond Imp Mills Pulverizers parts accessories. Wabash Power Equipment Co.• Tel: • Tel: ... in the vertical mill include GRAPHITE, TALC, COCOA, LIMESTONE, KAOLIN, PHARMACEUTICALS, and ...

Baileigh Industrial® Holdings LLC. distributes exclusively manufactured metal and woodworking machinery, trusted by customers ranging from largescale commercial fabrication shops to passionate hobbyists. For 20 years, we''ve created machines that increase productivity, day in, day out, delivering repeatable quality results.. At Baileigh (pronounced "Bailey"), we build our cuttingedge ...

Vertical Mills Baileigh has a metal milling machine to fit your needs and budget, whether you''re working in your garage or a large industrial shop. We offer 2 vertical mill lines: economical E models and production mills that last for decades.

Grinding roller is core part of vertical mill. SYMMEN METAL Casting can provide customized service according to customers''different processing requirements. Besides, it provides finished product manufacturing service for grinding roller including casting, finished machining, surfacing welding, etc.

Stationary Roller Mill Stationary Rollermill provides efficient milling using lower HP. Today''s feeding operations are now recognizing the advantages of rolled grain. Art''sWay''s Stationary Rollermill provides you with efficient milling for top quality feed from your corn or small grains and does it .

Wheel hub is the core part of grinding roller assembly. The roller cover is fixed on the hub, and the hub is installed on roller shaft, which forms the grinding roller assembly. Generally speaking, roller shell and wheel hub is connected together in the tapered structure, which is .

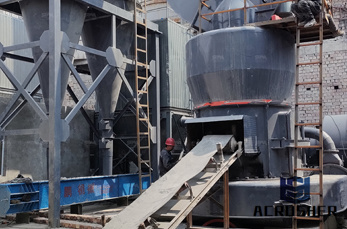

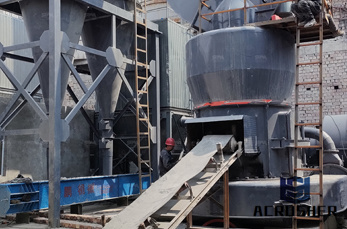

Vertical roller mill is a kind of grinding machine for cement raw material, cement clinker, slag and coal slag. It has the features of simple structure, low cost of manufacture and use. Vertical roller mill has many different forms, but it works basically the same.

vertical mill . This is a Fray "universal angle" head without quill feed, mounted on an ancient base for a Pratt Whitney #2 horizontal mill. horizontal mill (big, fullsize Kempsmith #2 unit in the garage) (closeup picture) (pic of me mill) . Still haven''t used it much, due to lack of projects for it.

HLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology. It features in a combination of drying, grinding, classifying and conveying. HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process ...

is employed for coal grinding mills and mills in the cement and industrial minerals industry. 2, 3, 4 or even 6 grinding roller configurations for a single grinding table can be realised. The first Type LM D modular coal grinding mills were developed in 1980 and employed for 12 times 2x600 MW power sta

vertical roller mill,vertical mills,vertical milling machine . vertical mills also named vertical roller mill or vertical milling . and convenient cone crusher is connected with locking sleeve assembly. .

Columbia Steel offers a broad range of durable replacement parts for vertical roller mills, including tires, grinding ring segments, armor rings and more. Columbia Steel Casting Co., Inc. Wear Parts .

The Williams Roller Mills are designed to provide years of reliable, consistent, and efficient operation, but the reason why Williams is one of the leading roller mill manufacturers is their ease of use and maintenance. Learn more about the features of the Williams roller mill crushers to see why they should be your top choice.

WhatsApp)

WhatsApp)