Ships For Sale – Classifieds For All Ships

Clean trading LR1 Panamax Oil Tanker is for sale. Owner invite best offers in line with market. MT TBN ITL FLAG ABT 70,313 MDWT ON BLT JUN/2004 DAEWO...

WhatsApp)

WhatsApp)

Clean trading LR1 Panamax Oil Tanker is for sale. Owner invite best offers in line with market. MT TBN ITL FLAG ABT 70,313 MDWT ON BLT JUN/2004 DAEWO...

Jan 23, 2017· What does asbestos look like – is a question often asked by homeowners and building contractors. Unfortunately, this question is not as straightforward as it sounds. Asbestos can take many different forms. Over the course of the 20th century (and even before then), asbestos was used as a common ingredient in a number of different building ...

The LongTerm Performance of Surface Support Liners for Ground Control in A Underground Limestone Mine ... this paper is to evaluate the preliminary findings of a longterm underground study of various types of surface support liners, and to examine installation practices that are critical for an effective liner material ... Latex/cement thin ...

How to construct a chimney crown Make sure it allows for expansion and contraction and sheds water By Carolyn Schierhorn T h i s s t e e l c ro w n f o r m f e a t u re s a b u i l t i n d r i p e d g e a n d 1⁄ 2x ⁄ 2 i n c h s u p p o r t tabs in each inside corn e r. The tabs .

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum .

A recent development in liner design is the DUOLIFT liner available from from CEMENT 3 at Alexandria University

Annexure ''A'' to Directors'' Report250 Кб. Replaced intermediate diaphragm, feed head liner and regraded grinding media of Cement Mill # 2. Replaced first chamber shell, liner plate and regraded grindingresources h) Development and use of Cement Grinding aid and accelerators for PPC PSC for improved performance in Concrete and...

Back to those who promote this technology : an online leaflet (Vega) advances figures comparing an old second chamber liner (Dragpeb) with their classifying liners. Here they get/claims great achievement. To note that Dragpeb were Tiletype liners FL used to promote.

To tackle a doityourself plumbing project, you need to know how to recognize different types of pipes. Recognizing the different types of pipes within your house is vital to knowing the right repair technique. The most common pipes used today are copper, PVC, or ABS. However, when dealing with older homes, you might encounter a [.]

Cement mill 1st 2nd chamber load. Dear Experts, I read some where that in cement 2chamber ball mills 1st chamber grinding media . mt/m3 and in 2nd chamber it is more mt/m3.

Cast in place chimney liners ( poured in place or pumped masonry liners) are made from a volcanic rock which makes the liner fireproof. Within the rocks are also thousands of microscopic air pockets which makes it very light weight with an excellent thermally insulated quality.

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize "just in case". Well, this safety factor can cost you much in recovery and/or mill liner wear and tear.

Construction documents often specify a cement type based on the required performance of the concrete or the placement conditions. Certain cement manufacturing plants only produce certain types of portland cement. What are the differences in these cement types and how are they tested, produced, and identified in practice?

Jan 17, 2014· This is my second old home, and I find myself so envious that you had your original heating system! In my first house (3800 square feet, built in 1900), a previous owner had removed the radiators and furnace, and replaced them with electric baseboard. Running that heat was ridiculously expensive, so we wound up installing a wood/coal/oil furnace.

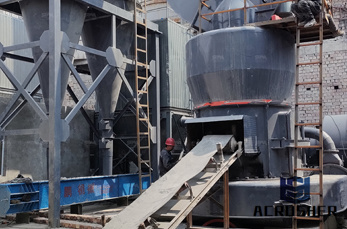

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

A sectional view of the singletoggle type of jaw crusher is shown below. In one respect, the working principle and application of this machine is similar to the Dodge crushers; the movable jaw has its maximum movement at the top of the crushing chamber, and minimum movement at the discharge motion is, however, a more complex one than the Dodge motion, being the resultant of the ...

Ball Mill Application The ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powdermaking production line including cement, silicate, newtype building materialThere are ladder liner and ripple liner and different specifications of steel balls in the chamber.

happen in one pass through the chamber (multicompression). The top part of the chamber is designed to have a big nip and is used to crush. As soon as the material is crushed and goes along the chamber, the bed is formed and the interparticle effect takes place. 20% of the total length of the wear liners is used to grind the bed of material.

Big capacity cement plant ball mill type for sale from China supplier cement plant ball mill type for sale from China supplier. ... In the second chamber, there are flat liners and steel ball, after the secondary grinding, material is discharged from the discharging. Add to Compare.

An Overview Of Lime Slaking And Factors That Affect The Process By: Mohamad Hassibi Chemco Systems, ... The second chamber is usually used as a grit removal chamber. The ... attritor type vertical ball mill lime slaker. The ball mill slakers are equipped .

Cement – Tube mill internals – Shell liners LINERS MADE TO LAST LONGER IN CEMENT MANUFACTURING The Group Industries manufactures Inlet discharge Head, First Chamber and Second Chamber Liners to provide optimum productivity and power consumption for all types of Tube Mill used in the Cement industry.

Subscribe to International Cement Review. 12 issues of the leading cement industry magazine, your choice of complimentary handbook, plus unlimited access to News, Articles and HD Videos. £ 205 / US 315 / EUR 260

grinding the resulting clinker to make cement (see Cement mill). In the second stage, the rawmix is fed into the kiln and gradually heated by contact with the hot gases from combustion of the kiln fuel. Successive chemical reactions take place as the temperature of the rawmix rises: 70 to 110 °C Free water is evaporated.

less grinding media will be consumed. Second, since the wasteful impact breakage of balltoball or balltoliner is eliminated, there are fewer ball fractures and the media inside the mill can maintain its shape and usefulness. Green Technology Energy efficiency and environmental consciousness is .

WhatsApp)

WhatsApp)