Can blackpowder be made without a ball mill ...

Sep 29, 2017· Page 1 of 2 Can blackpowder be made without a ball mill? posted in Pyrotechnics: I dont have a ball mill and I was curious if using a pestled .

WhatsApp)

WhatsApp)

Sep 29, 2017· Page 1 of 2 Can blackpowder be made without a ball mill? posted in Pyrotechnics: I dont have a ball mill and I was curious if using a pestled .

Jan 31, 2008· I put this ball mill together using a second hand 12 volt motor (20NZ) and a few old scraps from around the workshop. The tin holds 1 litre. I used lead fishing sinkers, the largest I could find ...

Haoyang steel balls manufacturing plant was put into operation in June, we deal with continuously growing consumer requirements for operational properties of grinding media, what directly affects ball mill prices and quality, efficiency of equipment and the enterprise in general.

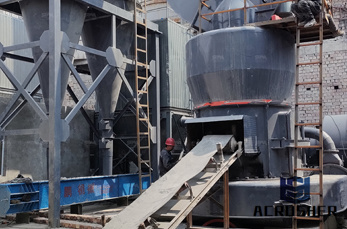

The ball mill equipment developed by FTM Machinery is a ball grinding machine, which uses steel balls as the grinding medium. And the ball mill grinder is mainly used for grinding cement, silicate products, new building materials, refractory materials, fertilizers, various ores and glass ceramics, etc.

Apr 07, 2011· How to Make a Ball Mill. Ball mills are a special instrument used to break up hard solids into a fine powder. They are similar to rock tumblers in that the instrument is a rotating container filled with heavy balls to grind the substance...

China Ball Mill Machine manufacturers Select 2019 high quality Ball Mill Machine products in best price from certified Chinese Mill Equipment manufacturers, Grinding Mill suppliers, wholesalers and factory on

Buy used Ballmills from King Industries. We can help guide you to the best solution for your equipment needs.

Cobra Carbide 23378 Micro Grain Solid Carbide Regular Length General End Mill, ...

Industrial ball mills made available by us are fabricated using qualityapproved mild steel stainless steel, and are used to grind materials into extremely fine powder. Owing to the quality and efficiency of our equipment, these find widespread demand for processing mineral dressing, paints, pyrotechnics and ceramics, among others. ...

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

Make a Ball Mill in 5 Minutes: This is for all the pyro nuts that I came across on Instructables. This can be used to grind chemicals to a very fine grain or to polish says "A ball mill is a type of grinder used to grind materials into extremely fine powder for use i...

Ball mill. A typical type of fine grinder is the ball slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the tumbling balls. Ball mills normally operate with an approximate ball charge of 30%.

Ball mills are commonly used for crushing and grinding the materials into an extremely fine form. The ball mill contains a hollow cylindrical shell that rotates about its axis. This cylinder is filled with balls that are made of stainless steel or rubber to the material contained in it.

Like all ball mills, the speed and ball size have an effect on how the vertical ball mill works. Vertical ball mills often come with a variety of ball sizes (and have variable speed settings) for more efficient processing. Industrial Ball Mills. Industrial ball mills are much larger than the other types of ball mills.

Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials. The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications.

Peter Pugger Ball Mill Jars: These deluxe ball mill jars are made of high quality porcelain and are designed to be used in conjunction with the Peter Pugger Double Ball Mill. The deluxe jars have a large mouth and thicker walls than standard jars.

Yantra Laboratory Ball Mill 2 kg Motor Driven Heavy Duty with 10 Big Stainless Steel Balls (15 mm) and 35 Small Stainless Steel Balls (8 mm)

Jan 28, 2016· MILLING BALLS Milling balls were and still are used in rotating drums known as ball mills, to reduce the size of particulate materials by tumbling and grinding. Older examples were made from hardstones including agate and flint or as ceramics from fired .

The surface of the cast grinding steel ball is not allowed to have the casting defects such as the crack, and the obvious gas porosity, inclusion, shrinking cavity, cold shut, elephant skin, etc. It is not allowed to have the shrinkage cavity, shrinking porosity, gas porosity, inclusion, and other cavity defects on the section including plane pasting through the pouring gate and the ball centre.

Ball mills tumble iron or steel balls with the ore. The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel. The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones.

in modeling and control of the grinding process in industrial ball mills. Basic ... density balls are made with a high alumina oxide content and they are more. Get Price. How I built a quick and easy homemade ball mill. How I built a homemade, quick and easy ball mill, that can also be used as a rock tumbler.

China Ball Mill manufacturers Select 2019 high quality Ball Mill products in best price from certified Chinese Plastic Machinery manufacturers, Milling Machine suppliers, wholesalers and factory on Madein .

Manufacturer of balls includes ball mill balls. Specifications of ball mills include 12 in. x 12 in. cast iron drum size, 285 ball charge, one to two phase, 110 to 440 V voltage, cycles in the range of fifty to sixty lbs. iron ball charge weight. Ball mills are available with iron stands, receiving hand screen pans digital counters.

Ball mill grinding media and milling media are used in milling or grinding processes to crush, grind and mill various materials. MSE Supplies offers a wide variety of grinding media and ball milling media with the package size ranging from kg and tons.

WhatsApp)

WhatsApp)